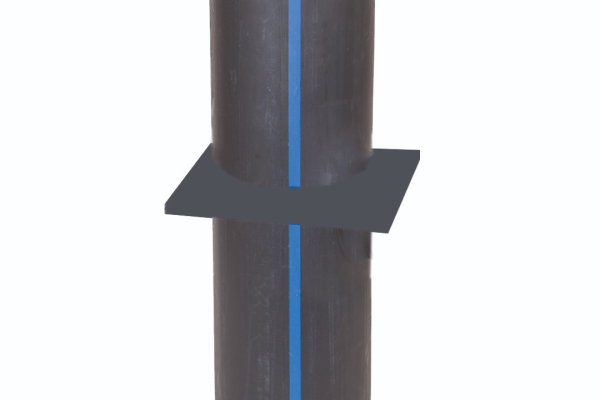

Top Applications of HDPE Puddle Flanges in Underground Piping Systems

Underground piping systems form the backbone of Dubai’s sophisticated infrastructure, silently supporting the emirate’s rapid development. Among the critical components ensuring these systems operate flawlessly are HDPE puddle flanges. As Dubai continues its ambitious construction and infrastructure projects, understanding how these specialized components contribute to system integrity becomes increasingly important for engineers, contractors, and project managers.

Water Storage Tank Penetrations

The United Arab Emirates considers water security as its most important concern while large-scale water storage facilities need dependable sealing solutions. Relevant applications in concrete wall penetrations find HDPE puddle flanges as excellent solutions because they protect both structural strength and moisture security. The water storage facilities in Dubai achieve watertight seals between concrete tank walls and HDPE piping systems through the employment of these flanges.

Underground Drainage Systems

The city of Dubai needs proper stormwater management solutions to address stormwater runoff during its sporadic heavy rainfall seasons. The use of HDPE puddle flanges exists as a critical element to ensure drainage pipes maintain full watertight integrity when they penetrate concrete collection chambers and retention basins and beneath-ground storage structures. These important connection points achieve total watertightness because the flanges block groundwater from entering and exceeding system capacity.

Foundation Wall Penetrations

The skyline of Dubai contains numerous buildings that extend their underground infrastructure into multiple basements deep beneath the surface. Thorough protection against water entry occurs when utility lines need to pass through foundation walls using HDPE puddle flanges as a barrier. The flanges establish leak-proof barriers to defend below-grade areas from water damage at foundation wall pipe penetrations.

Underground Fuel Storage Systems

Dubai’s transportation and energy infrastructure relies on comprehensive fuel storage and distribution systems. HDPE puddle flanges find important applications in underground fuel tank installations, where they create critical environmental protection at pipe entry points. The flanges prevent fuel leakage into the surrounding soil while simultaneously blocking groundwater from entering the system.

District Cooling Infrastructure

Dubai’s climate necessitates extensive cooling systems, with district cooling representing an efficient solution widely implemented throughout the emirate. The underground distribution networks for these systems utilize HDPE puddle flanges where pipes penetrate concrete valve chambers, pumping stations, and connection vaults.

The temperature fluctuations in cooling systems create expansion and contraction cycles that standard sealing methods struggle to accommodate. Purpose-designed puddle flanges maintain watertight integrity despite these dimensional changes, protecting sensitive equipment housed in underground structures from water damage while containing valuable coolant within the system.

Desalination Plant Components

Dubai’s freshwater supply relies heavily on desalination technology, with massive coastal facilities processing seawater through complex piping systems. HDPE puddle flanges serve critical functions where these pipes penetrate concrete structures in both intake and output sections of desalination plants.

The corrosion resistance of HDPE material makes these flanges ideal for seawater applications where metal components would quickly degrade. By maintaining absolute seals at concrete penetrations, the flanges prevent untreated seawater from contaminating processed water streams while simultaneously protecting concrete structures from saltwater exposure that could compromise structural integrity.

Installation Considerations in Dubai’s Environment

Dubai’s unique climate presents specific challenges for underground piping components. HDPE puddle flanges must withstand extreme heat, occasional heavy rainfall events, and highly saline groundwater conditions. Professional installation remains essential, with proper concrete vibration around the flange collar ensuring void-free embedment that maintains seal integrity