Why Go for HDPE Fabrication and Customization for Fittings?

Choosing the right materials for industrial fittings makes a big difference in project success. High-Density Polyethylene (HDPE) stands out as a smart choice for many businesses. Let’s explore why HDPE fabrication and customization services are becoming increasingly popular for various industrial applications.

Understanding HDPE Materials

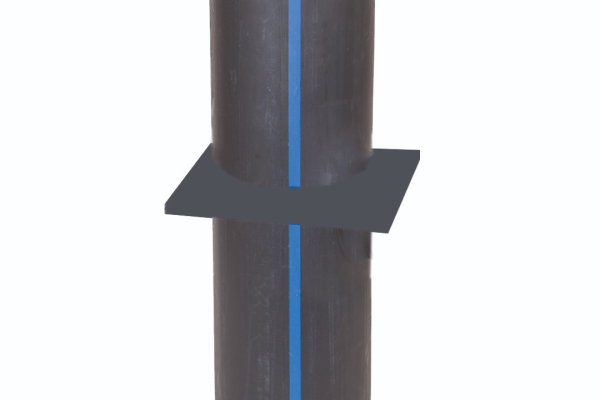

HDPE is a versatile plastic material that offers excellent strength and durability. When you work with HDPE fabrication and customization UAE specialists, you get products that resist chemicals, handle temperature changes well, and last for many years. These properties make HDPE perfect for pipes, fittings, and custom industrial parts.

Key Benefits of HDPE

Here’s what makes HDPE stand out for industrial applications:

- Strong resistance to chemicals and corrosion

- Excellent durability in harsh weather conditions

- Lightweight but tough structure

- Easy to customize for specific needs

- Cost-effective over long-term use

- Simple maintenance requirements

HDPE fabrication and customization services allow businesses to get exactly what they need. Instead of settling for standard parts that might not fit perfectly, companies can order custom-made fittings. This means better performance, easier installation, and fewer problems down the line.

Benefits of HDPE Fabrication and Customization

When you choose professional HDPE fabrication and customization providers, you get consistent quality in every piece. These specialists use modern equipment and follow strict quality control measures. This attention to detail ensures that each fitting meets exact specifications and performs reliably.

Cost-Effective Solutions

While some might think custom solutions are expensive, HDPE fabrication actually saves money over time. Custom fittings work better, last longer, and need less maintenance than standard parts. This means fewer replacements and repairs, which helps reduce long-term costs.

Easy Maintenance

HDPE fabrication and customization UAE experts create parts that are easy to install and maintain. The lightweight nature of HDPE makes installation simpler compared to metal alternatives. Plus, these fittings don’t need special coatings or frequent maintenance to keep working well.

Applications Across Industries

HDPE custom fittings work great in many different settings. They’re used in water treatment plants, chemical processing facilities, construction projects, and manufacturing plants. The material’s versatility makes it suitable for both simple and complex applications.

Working with HDPE Specialists

When choosing an HDPE fabrication and customization UAE provider, look for experience and technical knowledge. Good providers help you understand what’s possible with HDPE and suggest the best solutions for your needs. They should offer clear communication throughout the fabrication process.

Professional fabricators help plan your project from start to finish. They consider factors like temperature ranges, chemical exposure, and pressure requirements. This careful planning ensures that custom fittings work perfectly in their intended environment.

HDPE is an environmentally responsible choice. The material lasts a long time, which means less waste. It’s also recyclable, making it a good option for companies focusing on sustainability. When you work with HDPE fabrication specialists, they can help you make environmentally smart choices.

Picking the right HDPE fabrication partner matters. Look for companies with good track records, proper certifications, and modern equipment. The best providers combine technical expertise with good customer service to deliver exactly what you need.

HDPE fabrication and customization offers a perfect balance of quality, durability, and cost-effectiveness. By choosing experienced providers, you get custom solutions that fit your exact needs while maintaining high quality standards. This combination makes HDPE an excellent choice for industrial fittings and custom parts